How To Make Your Industrial Air Compressor Operate More Efficiently

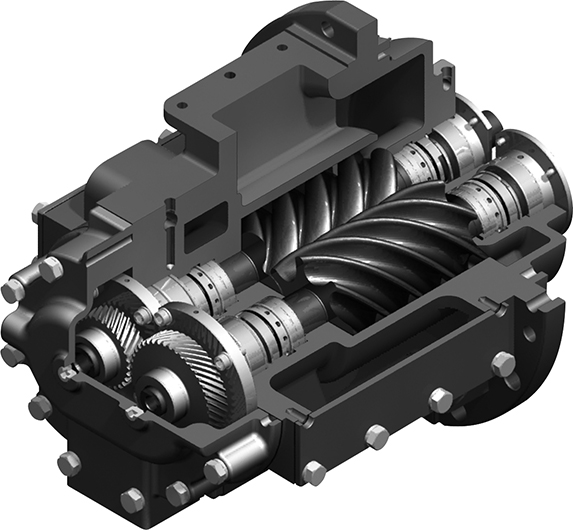

It's no secret in the industry that compressed air is the least efficient form of energy in the workshop. Unfortunately, rotary screw air compressors are very inefficient in design.

Electricity enters the plant from the utility pole and does not produce energy until it rotates the screw compressor, closes the air duct, flows through the workshop to its desired destination, and finally generates or works through a cylinder or pneumatic device. You can also visit compressedair.net.au/screw-air-compressors/ to buy the best screw air compressors.

Image Source: Google

This complex system has many waste options. The key to saving energy and producing the most useful pneumatic energy for the least amount of money is analysis and monitoring.

An air compressor is not just a machine. Since the air compressor produces energy, it must be treated as a system, so the compressor becomes a compressed air system. Start by listing the air usage and cfm and design pressures.

Identify and track leaks, most of which should be easy to find as they are often near the endpoint. Once the leak is identified, start repairing, of course, the largest air leak across the board.

Installing a flow meter on the mainline is also useful for understanding the savings in terms of cfm. The compressed air system should also operate at the lowest possible pressure after some of the larger leaks have been repaired.

Compressed air systems are complex systems that require constant monitoring. Saving energy costs is a priority for any factory or industrial facility, and rebellious air compressors can generate a lot of waste.